Services

We deliver a comprehensive range of services, including but not limited to:

Turnkey Electrical Projects

A turnkey electrical project provides a complete electrical system or infrastructure solution, managed from start to finish by a single contractor or service provider. This means the client doesn't need to manage different aspects of the project and can simply "turn the key" to operate the system upon completion.

Installation MV GIS, MV AIS, LV & PMCC Panels

Installing Medium Voltage (MV) Gas-Insulated Switchgear (GIS), Medium Voltage (MV) Air-Insulated Switchgear (AIS), Low Voltage (LV) & Power Management and Control Centers (PMCC) panels involves ensuring proper connection, testing, and commissioning of the equipment. This process typically includes a pre-installation inspection, physical installation of the panels and associated equipment, and a post-installation test to confirm correct operation.

Installation of Power Transformer & Distribution Transformer

Installing both power and distribution transformers involves similar fundamental steps: site preparation, lifting and positioning, electrical connections, grounding, and commissioning. However, power transformers, due to their size and weight, often require specialized lifting equipment and more complex grounding procedures compared to distribution transformers.

RMU & CSS Installation

The main functions of a Ring Main Unit (RMU) are circuit control, isolation from faulty equipment, and controlling circuits to switch functions. The main ring unit is deployed in a secondary distribution system. It is mostly utilized to provide an uninterrupted power supply.

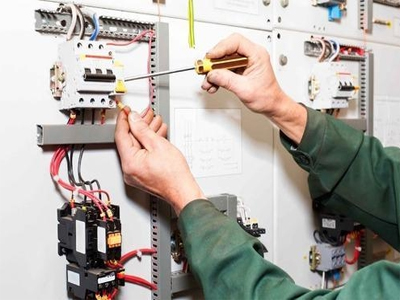

AMC / Breaker Servicing

AMC, or Annual Maintenance Contract, for electrical systems, including breakers, provides regular inspections, maintenance, and support to ensure efficient and safe operation. This service helps extend the lifespan of equipment, minimize downtime, and enhance safety. Breaker servicing specifically includes tasks like cleaning, lubrication, contact inspection, and testing to prevent failures and ensure proper operation.

33kV and 11KV HT, LT Cable laying & Termination

Laying and terminating 33kV and 11kV High Tension (HT) and Low Tension (LT) cables involves several key steps, including cable preparation, jointing, and termination. It's a process that requires specialized skills and equipment to ensure a secure and reliable electrical connection, especially for high-voltage applications.

UPS & Battery banks Supply & Installation

An uninterruptible power supply (UPS) or uninterruptible power source is a type of continual power system that provides automated backup electric power to a load when the input power source or mains power fails.

Control Cable Laying and Termination

Control cable laying and termination involves the careful installation and connection of control cables, typically used for electrical systems, ensuring proper functionality and safety. This process includes laying the cables in designated routes, securing them with support structures like cable trays, and terminating them at equipment or devices using appropriate methods like crimping or compression

High Mast, Street Light Installation

High mast lighting is a type of site light fixture that is commonly used to illuminate large areas from a very high mounting height for storage, transportation, and pedestrian use and safety. High mast fixtures are typically mounted on poles 40 feet to 150 feet tall, with four to 16 fixtures mounted on each pole.

HT & LT Line Shifting Work

HT (High Tension) and LT (Low Tension) line shifting involves relocating existing power lines to accommodate new infrastructure projects or when existing lines are deemed unsafe or inefficient. This process typically includes site surveys, planning a new route, obtaining necessary permits, and physically shifting the lines.

Industrial & Residential Home wiring

Industrial and residential wiring differ significantly in voltage, phase, insulation, and installation methods to accommodate the varying needs of each application. Residential wiring uses single-phase power, while industrial wiring utilizes three-phase power, enabling greater output and handling of high-voltage equipment and multiple systems. Industrial wiring also features heavy-duty insulation and specialized outlets to protect against corrosive environments and power-hungry machinery.

Diesel Generator Installation

DG (Diesel Generator) set installation involves several key steps, including site selection, foundation preparation, electrical connections, fuel supply setup, and exhaust/ventilation systems. Proper installation is crucial for ensuring the DG set operates efficiently, safely, and in compliance with relevant regulations.

Earth Pit Work

Earth pit work involves creating and maintaining a grounding system to ensure electrical safety and prevent potential hazards. This system, which includes an earth pit, provides a low-resistance path for fault currents to flow safely into the ground, protecting equipment and people from electrical shocks. Regular testing and maintenance are crucial to ensure the earth pit continues to function effectively.

Cable Tray Work & MS Fabrication Work

Cable tray work and MS (Mild Steel) fabrication involve designing, fabricating, and installing systems for supporting and organizing electrical cables. This includes creating custom trays, fabricating support structures, and ensuring proper installation and protection for the cables.

Solar Plate and Solar Water Heater Installation

Installing solar panels and a solar water heater in Tathawade, Pimpri-Chinchwad, requires careful planning and professional expertise. Solar panels generate electricity for various home uses, while a solar water heater specifically heats water using solar energy. Both systems involve a degree of installation complexity and should ideally be handled by qualified professionals.

Solar Plant AMC

Solar AMC services include a Solar plant inspection to find out the problems and their causes, and the use of standard preventive measures to prevent future issues to ensure the system functions efficiently for many years.

Electrical Motor Installation Services

Involve the professional installation of electrical motors, ensuring they are correctly mounted, wired, and aligned. These services often include troubleshooting, repair, and maintenance of motors. Many companies offer these services, including those specializing in motor rewinding, repair, and general electrical services.

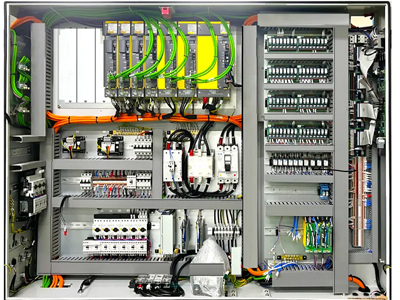

Panel Modification (PLC, Wiring, Automation)

Programmable Logic Controllers (PLCs) are industrial computers, with various inputs and outputs, used to control and monitor industrial equipment based on custom programming.PLC panel is a special steel box that contains electrical components required to run a factory machine or process. PLC stands for Programmable Logic Controller, an industrial hardened computer usually found inside factory control panels.

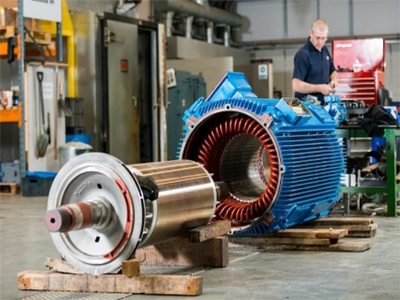

Motor Repairing & Rewinding

Motor repairing and rewinding involves restoring the functionality of an electric motor by replacing or repairing its damaged windings. This process is often a cost-effective alternative to replacing the entire motor, especially for larger or more expensive motors. Rewinding involves carefully removing the old windings, cleaning the motor core, and replacing them with new coils of wire.

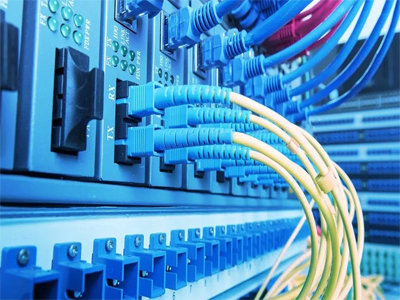

Fiber Optic Cable (Instrumentation Cable) Laying

Fiber optic cable laying, including instrumentation cables, involves installing the cable either overhead or underground using methods like blowing or pulling. Key steps include preparing the cable, determining the route, and then installing it through ducts, trenches, or cable trays. After installation, the system is tested and connected to active network components.

11 KV,33 KV Line Shifting Work

Shifting of 11 kV and 33 kV lines involves relocating or changing the route of these electrical power lines. This work is often necessary for various reasons, including road widening, construction projects, or to improve the distribution network. The process involves dismantling the existing lines, moving the poles and supporting infrastructure, and then reassembling the lines in the new location.